Creating new and innovative technologies is what you do. It’s a great feeling to know that you are providing useful hardware and inventions for users in all sorts of applications, as well as helping shape the future of technology and electronics.

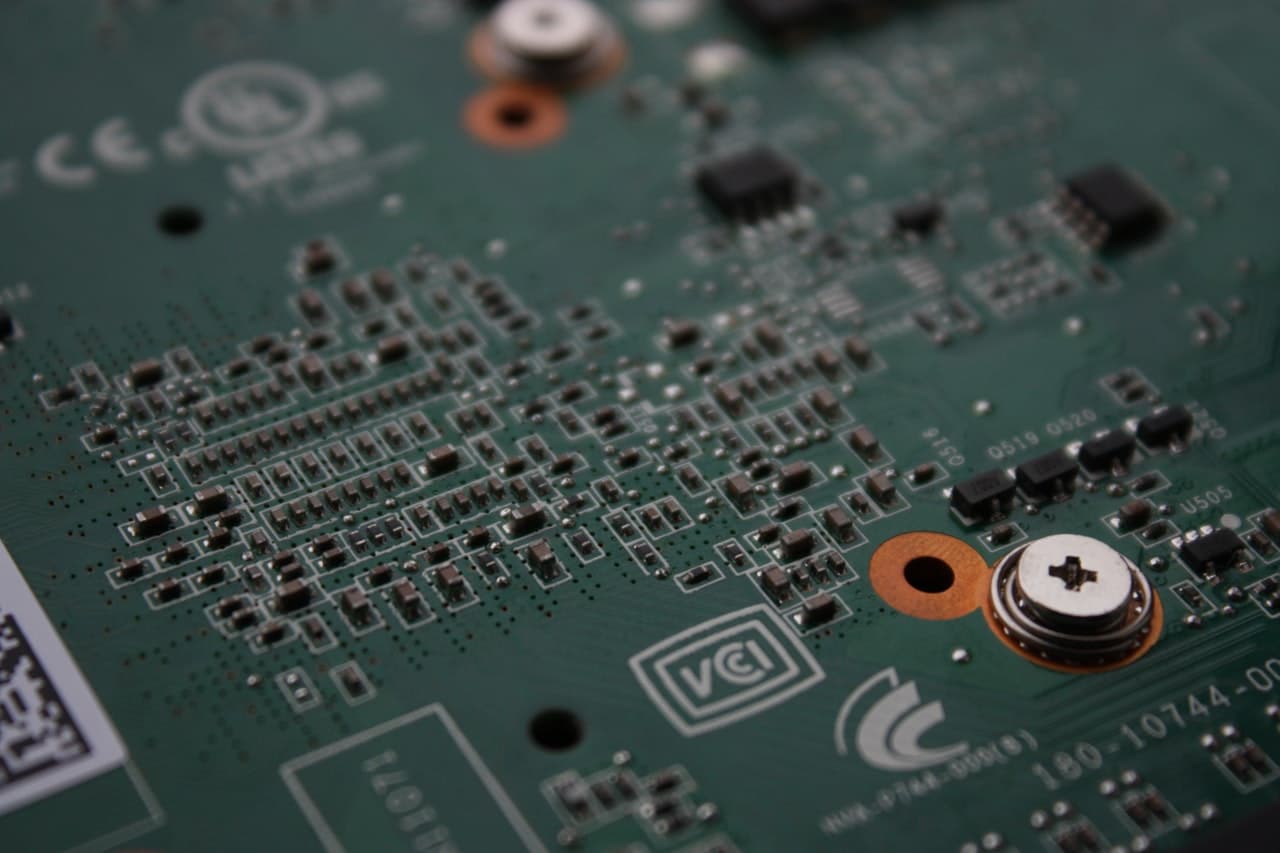

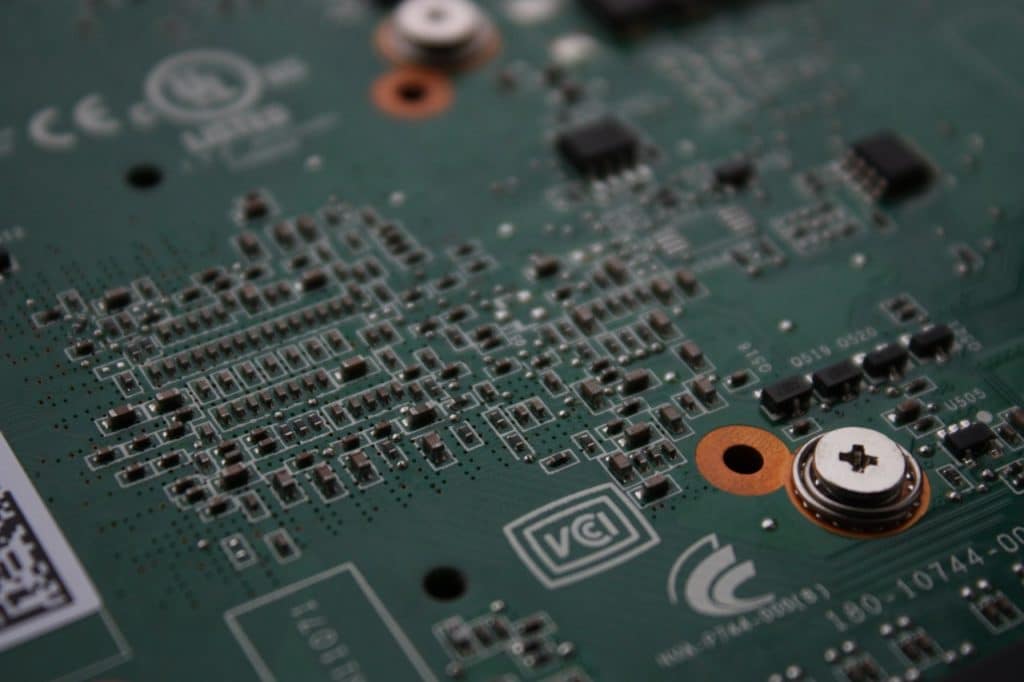

PCB assembly is a part of this process.

Coming up with the idea is the fun part. Imagining how that piece of equipment or new gadget will put smiles on the faces of its users is fun, too. What is not as fun is trying to figure out how to create that idea and formulate it into a working prototype and then get it manufactured to the world in the least expensive but most efficient way possible.

There are two significant types of manufacturing that you need to consider when working on an idea.

- Turnkey Manufacturing

- Consignment Manufacturing

We’ll take a look at both of these and offer information that should help you decide which best suits your needs.

Turnkey Manufacturing

Turnkey manufacturing allows you to outsource much of the work to someone who can create and manufacture your product. These people may be either a small or large business manufacturing operation. They can usually handle product assembly, acquisition of materials, product testing, warranties, and service after the sale.

The disadvantage (and the advantage) is that the partner that you turn over your job to gets complete control over the entire production process.

The advantages of this are that, once you turn it over to them, you don’t have to work about spending more overhead on operations, development, or manufacturing.

For creators who don’t mind turning over their project to someone they trust to put it together, this is a good option. It may also save money on overhead in the long run.

Consignment Manufacturing

Electronic consignment manufacturing is a technique whereby the inventor (you) would maintain full control over your manufacturing and supply process. Shipping, purchasing of materials, and inventory maintenance remains in the control of the inventor and developer. You would also monitor all materials, packing, and sorting of materials before it is handed over to the production and manufacturing facility for final assembly.

Using this method, you would maintain more control over making sure the materials were ordered correctly and that everything is in order before being passed on for manufacturing. This is a good extra security step that you may want to take especially if you have a product that is difficult to create or assemble or if you are unsure that the assemblers will spot a problem if there is one before the final product is rendered.

Which is best for me?

The method you choose is up to you, but you may want to explore the following questions before deciding.

- How much do I trust that the materials are correct and everything is in order before passing it onto my manufacturer?

- How well do I understand the process of my manufacturer and trust their expertise to troubleshoot problems as they arise before final manufacturing?

- What is my budget for production?

If you have a limited budget, you’ll want to pass it straight to the manufacturer rather than have the extra step that’s involved in consignment manufacturing.

As long as you understand and trust the ability of your design and manufacturing team and you have it all in one place, you should be able to enjoy the savings you’ll get with a turnkey system, while not worrying what the result will be.

MJS Designs can do this for you because they do all of this themselves. Contact them to find out how they can make the process streamlined by taking control over all of these processes including PCB assembly while keeping an eye on quality design results.