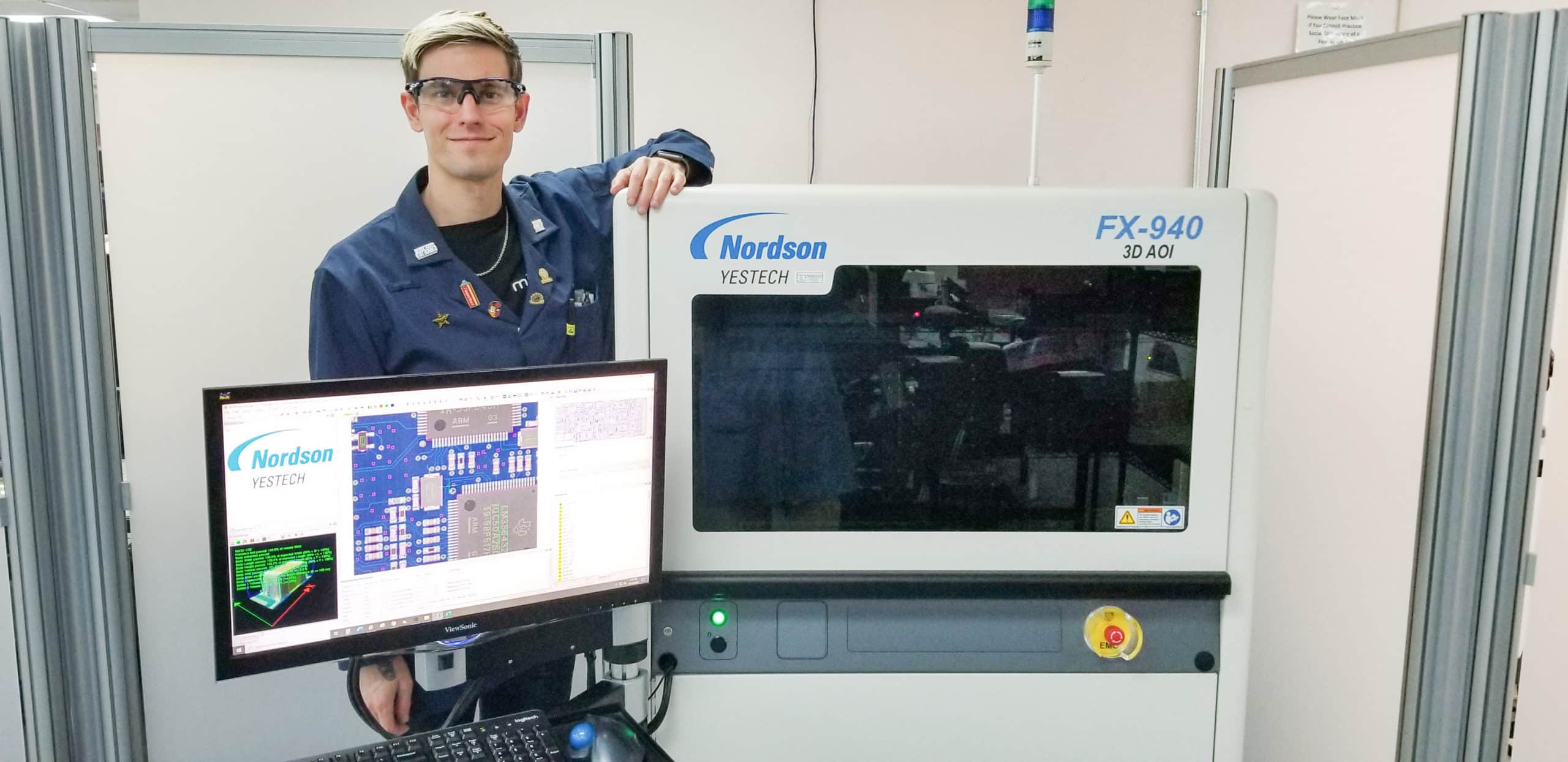

Resident authority, Matt Jefferies, explains a companywide commitment to PCB assemblies inspection with new 3D imaging technology.

At MJS Designs, our dedication to inspection and test is a point of pride. As a company, there have been sizable investments in both our people, like our own Matt Jefferies, and our tools, like our Nordson YESTECH FX-940 Automated Optical Inspection (AOI) System, known for high-speed inspections. Jefferies almost exclusively operates the FX-940 system during his workday.

Jefferies has been with MJS Designs for over 15 years, and has witnessed printed circuit boards (PCBs) becoming smaller and more complicated in his time. The complexities of his job have increased with technology and PCBs’ increased presence in more and more industries.

3D Automated Optical Inspection

AOI is a visual inspection system that confirms every component is placed correctly on the PCB. Using the bill of materials and X/Y pick-and-place data, every component on the board is researched and entered into the AOI program. The machine then verifies each component to ensure the accuracy of each part number, placement, polarity, and other data.

Jefferies is a great source of information with respect to AOI and why so many different industries depend on this type of inspection. He also holds the distinguished title of MJS Designs’ only IPC-A-610G certified instructor.

Jefferies says that the Nordson inspection system differentiates itself from previous systems with its incorporation of 3D, whereas previous machines were strictly visual.

Applying 3D technology in AOI machines is a universally amazing advancement, as operators can now observe all of the components’ measurements on PCBs while decreasing inspection time and increasing the accuracy of the inspection, per board. Traditional AOI machines rely on a purely visual inspection imaging capability that is known for an increased amount of false failures. Jefferies’ expertise, combined with the 3D cameras and tight tolerances of the AOI machine, simultaneously ensure the best of both human and automated inspection.

“We inspect every single board that comes through the building using an automated optical system,” noted Jefferies.

“The use of 3D inspection and elimination of batch sampling is a distinct benefit to our customers’ projects and what we offer as a company.”

Elimination of Batch Sampling

Batch sampling is the practice of testing components at a ratio other than 1:1. It is also known as acceptance of sampling by lots, in which MJS Designs does not engage.

“3D inspection accounts for not only placement, but also for the height of each component,” added Jefferies. “Every single board and its specific components or part numbers are all accounted for in every inspection, including part presence, manufacturer part numbers, and position.”

While the 3D AOI machine inspects for solder joints for Class 2 and Class 3 assemblies, MJS Designs still incorporates IPC-certified quality control technicians using microscopes as part of the solder inspection process, with 100% solder joint inspection.

Benefits of 3D Automated Optical Inspection

The end-user is the ultimate beneficiary. MJS Designs works across multiple industries at the highest level of technology development. This includes the defense industry, commercial and military aerospace industries, semiconductor and many other business sectors. A notable example is MJS Designs’ work on a PCB and inspection project that ended up on the Mars Rover, which studied the Martian surface.

MJS Designs will continue our investments in industry experts like Matthew Jefferies, our in-house authority on AOI, and our commitment to precision and dedication. Additionally, we are dedicated to investing in the tools, processes and systems that our detail-oriented experts will deploy across crucial technologies and industries.