In the ever-evolving realm of PCB assembly, ensuring the reliability and longevity of electronic components is of utmost importance. Standing in the way of this goal is Electrostatic Discharge (ESD), a potential threat that can irreparably damage sensitive components and result in costly failures. To properly navigate these risks, a thorough understanding of various ESD suppression methods is crucial. This blog will take a close look at different ESD mitigation strategies, including Heel & Wrist Straps, Benchtop Mats, Conductive Flooring, and other General Rules.

The Risk of ESD

Electrostatic Discharge occurs when an electric charge leaps between two objects with different electric potentials. A severe ESD event can cause immediate and complete damage to electronic components, rendering them non-functional right away. However, even in cases where the damage is not immediately apparent, ESD can subtly reduce the reliability of the chip, elevating the risk of latent failures over time. Understanding common sources such as human interaction, friction, and mishandling of electronic devices highlights the need for a comprehensive ESD prevention plan.

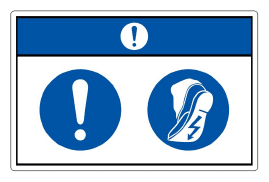

Heel & Wrist Straps

Heel and wrist straps serve as foundational elements in the defense against ESD. Heel straps consist of conductive material that securely attaches to the user’s shoe, establishing a direct connection between the user and a grounded floor. Simultaneously, wrist straps wrap around the user’s wrist and are secured with a conductive band, creating a second continuous path to ground. This redundant grounding method ensures that any accumulated static charge on the user’s body is rapidly dissipated, preventing potential discharge to sensitive electronic components.

Benchtop Mats and Conductive Flooring

Benchtop mats and conductive flooring play crucial roles in creating a controlled environment that minimizes the risk of ESD incidents during PCB assembly. Benchtop mats are made of dissipative materials that allow the controlled dissipation of static charges. By grounding these mats, all components and PCBs placed on the mat will be safely discharged. These mats are strategically placed on workbenches, providing a safe surface for handling electronic components.

Conductive flooring, on the other hand, is designed to establish a grounded foundation throughout the entire workspace. It is composed of materials with inherent conductivity, allowing static charges to flow harmlessly to ground. Conductive flooring, in conjunction with heel straps, keeps all personnel grounded throughout the facility. This grounding technique is critical for protecting against ESD events when wrist straps cannot be worn, such as moving between workbenches. When properly installed, conductive flooring provides a universal, base level of protection. This comprehensive approach to grounding significantly reduces the risk of ESD incidents, creating a secure environment for delicate electronic components.

ESD Smocks and Ionizers

In addition to grounding the environment and all personnel, the risk of ESD damage can be further minimized by using strategically placed ionizers. These ionizers work by emitting positive and negative ions into the air surrounding sensitive circuitry. The ions in the air are attracted to built-up charges, and work to neutralize them. This provides yet another layer of protection against ESD events.

Another vital component in a successful ESD mitigation strategy is the use of ESD smocks. The ESD smock serves as a protective shield, preventing static charges on the operator’s clothes from reaching the ESD-sensitive components. ESD smocks are crafted from static dissipative fabric, which captures any charges attempting to pass through. These charges are then systematically drained through the user’s grounded body via heel straps and/or wrist straps.

General Rules for ESD Mitigation

A comprehensive approach to ESD mitigation goes beyond just having the right tools and materials. It is also important to implement fundamental rules and procedures to maintain a proper ESD controlled area.

- Humidity Control: It is important to maintain a relative humidity level between 35-45%. This humidity range provides sufficient moisture in the air to dissipate static charges effectively, while avoiding excessive moisture that could lead to other issues like corrosion.

- Routine Testing: Regularly testing ESD equipment is essential to ensure its proper functionality. A malfunctioning wrist strap or benchtop mat may give a false sense of protection against ESD. Daily testing of heel and wrist straps, along with monthly testing of benchtop mats and conductive flooring, is recommended to maintain a reliable ESD prevention system.

- ESD Packaging: When it comes to shipping sensitive electronics, it is critical to use ESD packing materials, including static bags, stickers, bubble wrap, and foam. This ensures the safe shipment of ESD sensitive components and PCBs.

- ESD Training: To uphold industry standards, all personnel should undergo IPC ESD training every two years. This dedication to continuous education guarantees that every operator is adequately prepared to manage ESD risks.

Partnering with MJS Designs

At MJS Designs, we place a strong emphasis on ESD protection to serve crucial sectors like military, automotive, and aerospace, where steadfast reliability is non-negotiable. Our cutting-edge facility operates under stringent standards, maintaining an ESD class 0 manufacturing environment. Specializing in high reliability PCB manufacturing, we assure the highest level of protection for your electronic components.

Choosing MJS Designs as your PCB manufacturing partner guarantees an unwavering commitment to the integrity of your electronic devices. Our highly skilled team is well-versed in ESD suppression methods, adhering to industry best practices to ensure the success and dependability of your project. Safeguarding against ESD requires a deliberate combination of proactive measures, ranging from Heel & Wrist Straps to Conductive Flooring. MJS Designs implements these critical methods rigorously in our manufacturing processes to provide the highest quality of PCB manufacturing services available. Partner with us for ESD excellence, and rest assured in the longevity and reliability of your PCBs. Contact us here to get your project started.