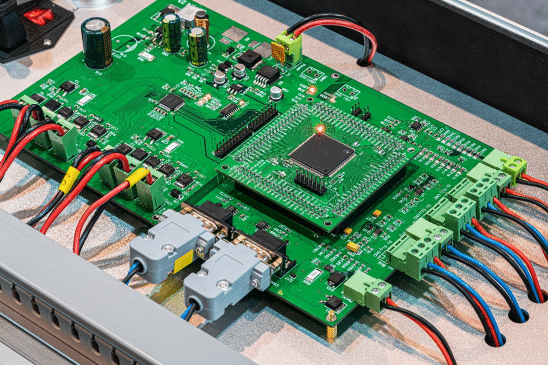

In the fast-evolving world of electronics, staying ahead of the curve is paramount to the success of any product. This is especially true in the realm of printed circuit boards (PCBs), where component unavailability and the discontinuation of vital parts can severely impact product development and manufacturing. Designing with component availability in mind is critical for developing long-lasting and reliable electronic products.

In this blog post we explore the intricacies of component obsolescence and highlight its potential impact on a product’s success. Additionally, we provide valuable insights into how MJS Designs’ embedded engineers adeptly navigate these challenges to extend the lifespan of your PCBs.

Understanding Component Obsolescence

Component obsolescence is a standard occurrence in the electronics industry in which a component manufacturer discontinues a product. Once obsolete, a component is no longer manufactured and becomes increasingly difficult, if not impossible, to procure. Manufactures choose to discontinue products due to many factors such as technological advancements, market fluctuations, and manufacturing decisions. Understanding the process behind obsolescence is crucial for embedded engineers to develop long-lasting products.

Costs of Component Shortages and Obsolescence

In the world of electronics manufacturing, component shortages can lead to an array of undesirable outcomes. One such issue is extended manufacturing lead times, which result from the unavailability of critical components. These component lead times can delay a project’s timeline by several months, and in more extreme instances, by over a year. Additionally, manufacturers may find themselves compelled to purchase more components than needed to meet suppliers’ minimum order requirements, incurring unnecessary costs. In extreme cases, a complete PCB redesign may be necessary to accommodate an available substitute, a time-consuming and costly endeavor that disrupts project schedules. An alternate component, one that offers equivalent function and fit, can serve as a valuable solution when a shortage or obsolescence occurs. However, when there are no available alternates, these challenges significantly impede the manufacturing process, underscoring the importance of proactive measures that address component obsolescence and availability.

Strategies for Navigating Component Obsolescence

Embedded engineers utilize a variety of strategies across different project phases to minimize the risks and effects of component obsolescence. These methods are seamlessly integrated into the product development, impacting everything from initial vendor relations, to the circuit design and component selection, and even the final stages of PCB layout. Several of the methods implemented by engineers at MJS Designs are described in detail below.

- Establishing Vendor Relationships: Forming strong relationships with component vendors allows MJS Designs to stay informed about product lifecycle statuses and any upcoming changes that may affect the supply chain. This also provides opportunities to gain priority access to new components or limited inventory ahead of other manufacturers.

- Practicing Modular Engineering: When designing circuitry, it is important to consider component modularity. Rather than relying on specialized, niche components for specific tasks, general-purpose circuitry can usually be used to replicate the required functionality. This approach serves as a safeguard against the potential obsolescence of non-standard components with no viable alternates.

- Selecting Industry Standard Components: Component selection is a quintessential factor in the lifecycle of a product. By selecting components with industry standard packaging and pinouts, engineers can maximize the alternative components available for a product’s design. If the original component is unavailable or obsolete, then an equivalent alternate can be utilized for a production build. This eliminates component lead times and, in the event of component obsolescence, prevents the need for a PCB redesign.

- Choosing Reliable Component Manufacturers: There are some components, such as FPGAs or embedded microcontrollers, that do not have alternates available for them. In this case, selecting a device from a reputable manufacturer offers a decreased risk of component obsolescence. Well established manufacturers have proven, flagship product lines that have been shown to withstand the test of time. A great example of this is the PIC18 family of microcontrollers from Microchip, which was first introduced in the late 1990’s and remains in active production today, with new components still being released.

- Staying Up-to-Date with Component Technology: Constant innovation from component manufacturers is leading to smaller, higher power, and more capable devices than ever. By staying familiar with the latest developments in the component industry, engineers can ensure they are picking cutting edge parts for new PCB designs. Using next-generation components not only increases the capabilities of a product, but also decreases the risk of component obsolescence.

- Designing for Adaptability: Incorporating design flexibility into a PCB helps future-proof the product, making it more adaptable to fluctuating component availability. This can be achieved by implementing dual footprints and ensuring compatibility with multiple components. For example, if there is a component in the design that does not have any alternates with the same package size or pinout, then a second footprint can be designed onto the board to accommodate other components. This provides additional risk mitigation for obsolete or out of stock components.

Conclusion

Component obsolescence is an ever-present challenge in PCB design. If not handled correctly, it can lead to excessive project delays and increased costs. While there is not a one-size-fits-all solution, understanding the dynamics, consequences, and strategies for addressing obsolescence contributes to the success of an electronic product development.

At MJS Designs, we appreciate the complexities of electronic product design and the importance of navigating component obsolescence. Our experienced team of engineers specializes in creating PCBs that prioritize longevity and adaptability. Whether you operate in the commercial, industrial, aerospace, or any other industry, we have the expertise to help you design products that endure. Contact us today to discover how MJS Designs can be your partner in designing reliable, long-lasting electronic solutions. Together, we will ensure your products remain at the forefront of innovation and maintain their competitive edge.