In today’s rapidly advancing technological landscape, printed circuit board assemblies (PCBAs) serve as the backbone of countless electronic devices, from smartphones to medical equipment. Ensuring the reliability and functionality of these PCBAs is paramount to the success of any electronic product. At MJS Designs, we understand the critical role that PCBA quality plays in the performance and longevity of electronic devices. As a leading manufacturer specializing in high-quality and high-reliability PCBA assembly projects, we implement a multi-pronged inspection approach to ensure the highest level of manufacturing quality.

The Importance of PCBA Inspection

Before a PCBA finds its way into a finished product, it undergoes a series of rigorous inspections to detect and rectify any manufacturing defects. These inspections not only ensure that the PCBA meets the required specifications but also guarantee its reliability and functionality once deployed in the field. At MJS Designs, we recognize the significance of PCBA inspection in delivering products that exceed our customers’ expectations.

In-Process Quality Control

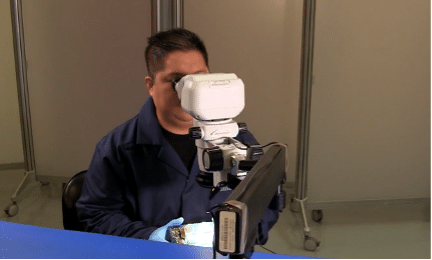

In-Process Quality Control (IPQC) is an integral part of our manufacturing process, where inspections are conducted at various stages of PCBA assembly. This proactive approach allows us to identify and address potential issues early on, minimizing the likelihood of defects propagating further down the line. IPQC involves a thorough visual inspection of all solder joints, verifying that the board meets the required IPC specifications. While MJS Designs’ manufacturing facility is rated for IPC class 3, boards are inspected to IPC class 2 or class 3, depending upon the project requirements.

X-Ray Inspection

Some solder joints are not visible on assembled boards, either due to component density, or placement of the component leads. Ball Grid Array (BGA) components, for example, have their solder connections under the body of the component. Even though these solder joints are hidden from view, they still require inspection to ensure they meet IPC standards. This can be done through an X-ray inspection. By using X-ray technology, MJS Designs is able to inspect the quality of these hidden solder joints, guaranteeing quality on even the densest PCBA assemblies.

Automated Optical Inspection

Once fully assembled, all PCBAs are machine inspected to ensure the highest level of manufacturing accuracy. Utilizing state-of-the-art technology, Automated Optical Inspection (AOI) enables us to detect minute defects that may escape the human eye. High-resolution cameras and advanced algorithms scan the PCBA surface, identifying issues such as soldering defects, misalignments, and missing components. AOI also looks at component markings, allowing it to verify component polarity and identify an incorrect component. By employing the latest AOI technologies, MJS Designs achieves consistent product quality and reliability.

Final Quality Assurance

Before leaving our facility, each PCBA undergoes a final round of quality assurance to ensure that it meets our uncompromising standards for quality and reliability. Final QA involves a comprehensive review of all inspection data, documentation verification, and visual inspections to confirm that the PCBA meets the customer’s specifications and regulatory requirements. Only PCBAs that pass our stringent QA criteria are approved for shipment.

MJS Designs’ Commitment to Excellence

At MJS Designs, we take immense pride in our commitment to delivering the highest quality PCBA assemblies to our customers through meticulous inspection and testing processes. Our dedication to quality is evident in every aspect of our operations, from initial design to final assembly. When you choose MJS Designs for your PCBA manufacturing needs, you can trust that you are partnering with a company that prioritizes quality, reliability, and customer satisfaction above all else. Contact us to experience the MJS Designs difference and elevate your electronic products to new heights of excellence.