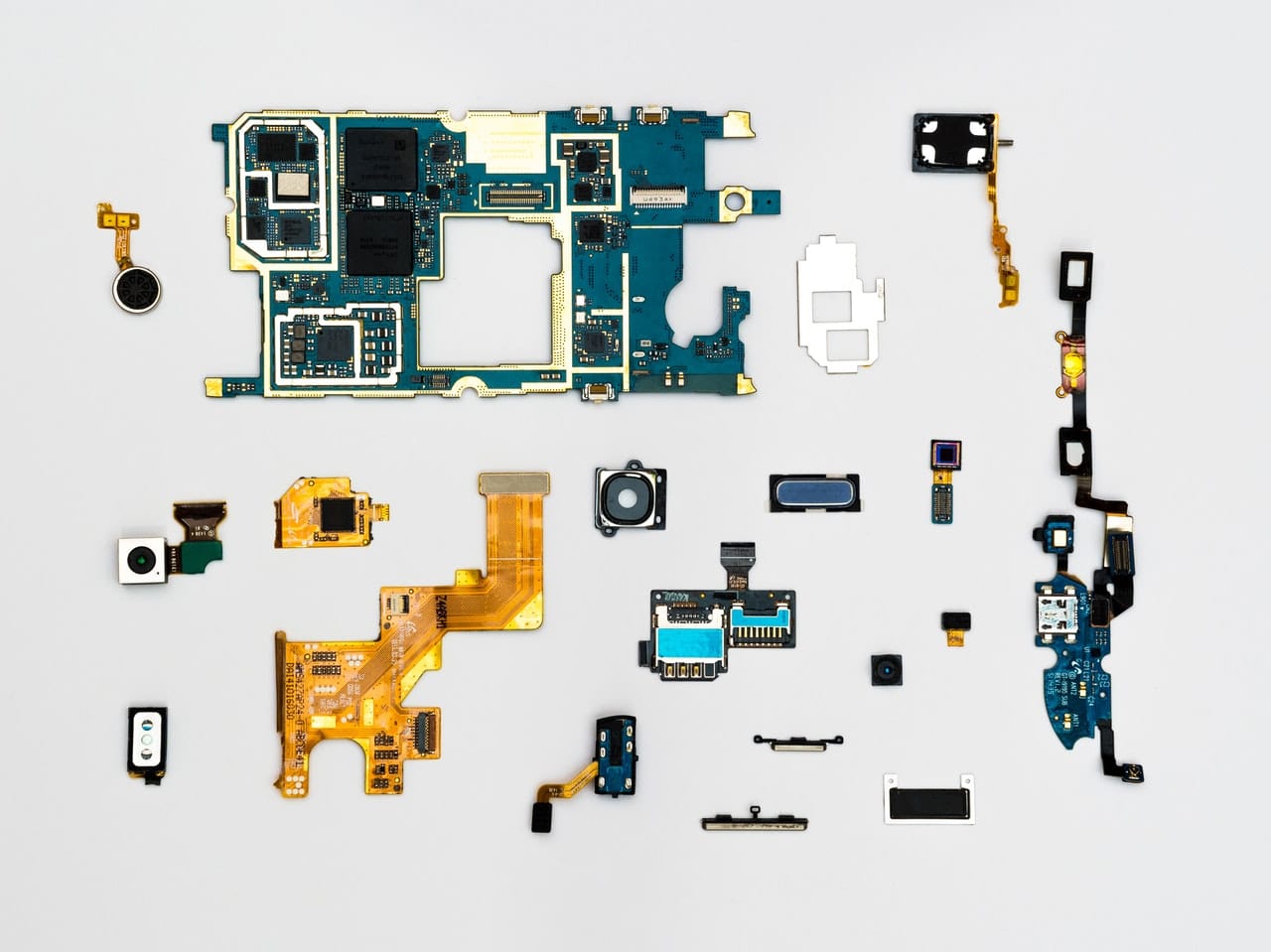

Where do you start to ensure that your idea becomes one of those great products that people will appreciate and love? Start by looking for professional electronics contract manufacturer and get familiar with these helpful tips.

1. Talk to a skilled PCB assembly USA engineer before you begin. Many people make the mistake of creating their design idea first and talking to engineers later. Engineers know what will work and what won’t, so it’s important that you first get the opinion of a design engineer before you proceed.

1. Talk to a skilled PCB assembly USA engineer before you begin. Many people make the mistake of creating their design idea first and talking to engineers later. Engineers know what will work and what won’t, so it’s important that you first get the opinion of a design engineer before you proceed.

2. Consider who your manufacturer will be. If you have decided to have your product created overseas, you will have to fly to the location many times to ensure that the quality you are putting out is what you intended, as well as to consider the total cost of production. China, for example, may quote low figures in your estimates, but the final bill may be much higher. You also have to include freight costs.

3. Find more than one supplier for parts. It’s great if you have a supplier that produces consistently good quality. But what if that one supplier runs out of product or goes out of business? It’s a good idea to have more than one supplier for your raw materials.

4. Labels should be consistent. What do your labels say about the product and your brand? Branding is important, and your label should be done in such a way that it entices the buyer as well as showing quality for your brand.

5. Make sure all parts in a package are easy to read and understand. Engineers and manufacturers need to be able to find the parts quickly so it won’t slow down the assembly process.

6. Use all resources and tools. Work with your design team to ensure that you utilize all of the tools and resources you have available. This should result in a better-finished product.

7. Consider file formats. Your designs should be readable by engineers and designers, no matter what type of computer they are working from.

8. Don’t sacrifice quality. Quality should be put first above all else. Customers demand it, and that’s why they buy from you. Buying cheaper parts may save you production costs, but it will cost you in sales.

9. Time is money. As is true of any type of business or product design, time is money. Consider the lead time, assembly time, and time to manufacture and distribute your product before you begin. You must count all of this into your cost of production.

10. Begin with the end in mind. The most successful ventures start with a vision of the end product. If you are clear on this idea, you’ll be able to successfully communicate it to your designer, who can produce the idea to a marketable product.

Conclusion

If you are looking for a skilled engineer and design team or PCB assembly USA, you can count on the professional team at MJS Designs. They have the skill, the time, and the expertise to produce your product with the high-quality specs you need to please your customer base.

If you are looking for a skilled engineer and design team or PCB assembly USA, you can count on the professional team at MJS Designs. They have the skill, the time, and the expertise to produce your product with the high-quality specs you need to please your customer base.

Contact them today for a free estimate and get your product to market tomorrow!