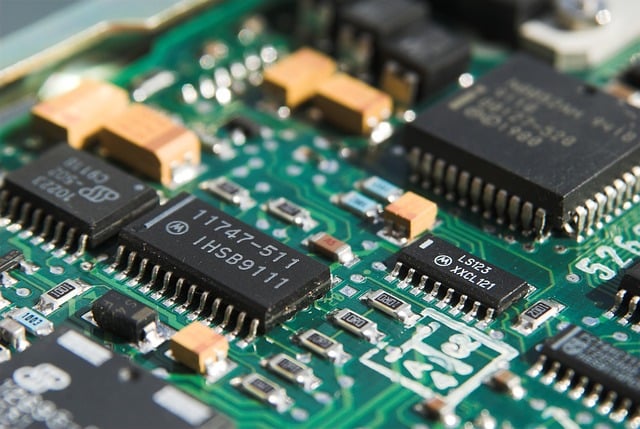

You already know about printed circuit boards and PCB design Arizona services. But are you aware of the differences between the standard printed circuit boards and flexible circuit boards?

Why use flex boards?

Flex circuit boards are more pliable and flexible than standard circuits, so they can bend and turn in ways that allow more freedom in the design and operation of your circuit board. They can also fit in tight spaces that may not be possible with standard parts. This means that designers can have the freedom to locate other parts of the component system so that it makes room for all parts more easily.

Flex circuit boards are more pliable and flexible than standard circuits, so they can bend and turn in ways that allow more freedom in the design and operation of your circuit board. They can also fit in tight spaces that may not be possible with standard parts. This means that designers can have the freedom to locate other parts of the component system so that it makes room for all parts more easily.

Save space and weight load

Another advantage of flexible circuits is that they save space and cut down on the weight load on the motherboard. Some designers have reported that they have saved up to 75% in space which allows for better stability in the heat dissipation. More features can be added to flexible systems due to the space that is saved with flexible circuit parts.

Reliability and Durability

Flex circuits may also be more reliable and durable than standard parts. The standard solder and handwired connectors of the standard board components are replaced by etched circuits on tile-like parts that can be easily duplicated when you send them to your manufacturer.

Flex board components may lower the number of wiring errors and it may mean better performance of your boards over the long term.

The production of the design that uses flexible circuits requires less manual labor requirements and reduces production problems and mistakes. It may also eliminate the high cost of production since there is no routing, wrapping, or soldering wire issue.

Interconnections

Flex boards use interconnected systems that are installed in a system rather than individual circuits. This cuts down on wiring errors and lowering the cost of production. For anyone who wants to produce a large number of their product using the more flexible printed circuit board technology, this is important because of the way it could potentially increase your ROI.

How to Increase the Applications Benefits

If you have decided to use flexible printed circuit boards in your design, you should know that you’ll get the most benefit by using conductive ink, additive circuitry, and anisotropic adhesives. Using flex circuits as an option will improve your product overall especially when you are producing units in high volume.

Disadvantages

There are many advantages to using flex boards. So what are the disadvantages? One is that it may be harder to find a manufacturer for flexible circuit parts since this is still a relatively new hardware that is not produced by every manufacturing company. Additionally, there may be challenges in production because you do not follow the same blueprint as you do with standard boards.

How to Get Started

Circuit boards are at the heart of your design. You have big goals of getting your product to market using the latest technologies such as flexible printed circuit board parts. But you need professional engineers and electronic manufacturers to get your product on the market.

Circuit boards are at the heart of your design. You have big goals of getting your product to market using the latest technologies such as flexible printed circuit board parts. But you need professional engineers and electronic manufacturers to get your product on the market.

That’s where we come in. At MJS Designs, we focus on the latest technologies including flexible circuit boards so that we can help you design the best possible product. Then we can test and mass (remove this word mass) produce your units so that you can get your product out there as soon as possible.

There’s a reason we say we offer “Electronics Manufacturing on a Fast Track.” We will get the job done fast but still maintain the high quality you demand.

Contact us for a free quote and see how we can help with your electronics and engineering projects.